Jaguar Land Rover (JLR) is poised to restart manufacturing operations across its West Midlands and Merseyside sites this Wednesday, marking a significant step in its recovery from a major cyberattack.

The luxury car maker has also unveiled a new financing scheme to aid struggling suppliers, offering upfront cash payments to qualifying firms affected by the security breach.

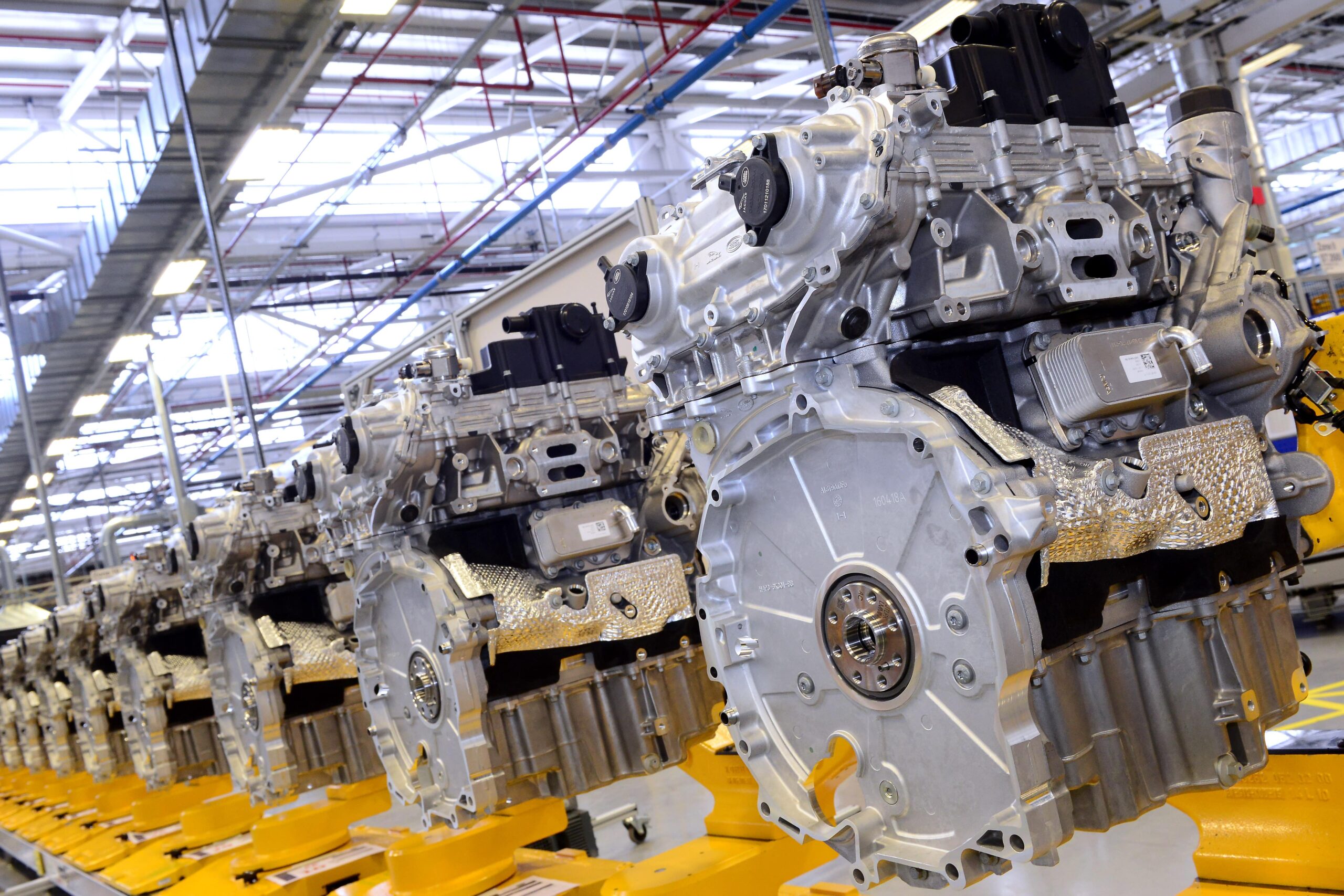

Production workers are scheduled to return as operations recommence at the Wolverhampton engine plant and the Coleshill, Birmingham, battery assembly centre from Wednesday.

The company will simultaneously reactivate its stamping facilities in Castle Bromwich, Halewood in Merseyside, and Solihull.

Crucial areas of its Solihull vehicle production plant, including the body shop, paint shop, and logistics operations centre – which supplies parts to JLR’s global manufacturing network – are also set to resume.

Further operational expansion is expected later this week, with the vehicle manufacturing plant in Nitra, Slovakia, and the Range Rover and Range Rover Sport production lines at the Solihull facility slated to follow suit.

Adrian Mardell, chief executive of JLR, said: “This week marks an important moment for JLR and all our stakeholders as we now restart our manufacturing operations following the cyber incident.

“From tomorrow, we will welcome back our colleagues at our engine production plant in Wolverhampton, shortly followed by our colleagues making our world-class cars at Nitra and Solihull.

“Our suppliers are central to our success, and today we are launching a new financing arrangement that will enable us to pay our suppliers early, using the strength of our balance sheet to support their cash flows.”

“We know there is much more to do, but our recovery is firmly underway,” he added.

JLR said it would update further on the next steps of its “controlled restart”, including its Halewood plant in Merseyside.

The group has halted all manufacturing since the start of September after being targeted by hackers.

Experts have warned the production shutdown could hit the group’s bottom line by around £120 million, with the firm usually thought to build about 1,000 cars a day.

The pause has also left its suppliers in limbo, leading to fears that small firms producing parts for the car giant could collapse without financial support.

JLR has the largest supply chain in the UK automotive sector, which employs around 120,000 people and is largely made up of small and medium-sized businesses.

The Government recently announced it would underwrite a £1.5 billion loan guarantee to JLR to give suppliers some certainty over payments, helping bolster JLR’s cash reserves, but calls mounted for more to be done.

JLR said on Tuesday that its extended support package would see suppliers paid much faster than under the usual payment terms, by as much as 120 days early.

It will start with qualifying JLR suppliers seen as critical to the restart of production, then will be expanded to cover some non-production suppliers who have also been affected.

JLR also vowed to pay back financing costs for those JLR suppliers who use the scheme during the restart phase.

The firm said it will also publish second-quarter results later on Tuesday.